- What is an encoder?

- What is an incremental encoder?

- What is an absolute encoder?

- What is an optical encoder?

- What is a magnetic encoder?

- What is an inductive encoder?

- What is the Energy Harvesting Technology?

- What is a linear transducer?

- What is the encoder code wheel?

- What is the mechanical interface?

- Which are the incremental electronic interfaces?

- What is the electronic interface?

- What is the analogue interface?

- What is the parallel interface?

- What are Gray and binary codes?

- What is the SSI interface?

- What is the BiSS interface?

- What is the Modbus protocol?

- What is the CANopen protocol?

- What is the Profibus protocol?

- What is the Profinet protocol?

- What is the EtherCAT protocol?

- How to read Eltra’s ordering code

What is an encoder?

The encoder is a transducer of position and speed which converts the angular or linear motion of a shaft (or axle) into a series of electrical digital pulses.

These electrical pulses are employed to control the motion of the mechanical shaft (that has generated them) as well as its displacement speed by operating on actuation devices of any type.

The encoder is formed by:

- Mechanical interface

- Code wheel (or magnetic actuator or linear scale)

- Optoelectronic receiver or magnetic sensors

- Electronic interface

Encoders use different technologies to detect the motion:

- Photoelectrical or optical scanning (for rotary or linear products)

- Magnetic field variation (for rotary or linear products)

- Potentiometric (for rotary or linear products)

- Magnetostrictive (for linear products)

- Energy Harvesting (for rotary products)

|

|

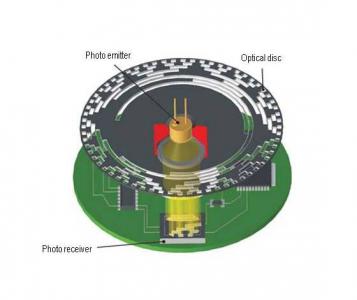

| Section of optical encoder | Section of magnetic encoder |

Main applications of rotary and linear transducers are: machine-tools, material processing machinery, robots, motor feedback systems, measure and motion control devices.

What is an incremental encoder?

The incremental encoder is so defined since it tracks the increase (variation) in relation to a position taken as a reference point, independently from the direction of rotation. The incremental encoder senses rotation, speed and acceleration by counting the number of pulses sent by the output circuit, although the zero point of the machine must be reset at every new start.

Incremental encoders can have 3 channels (A, B, Z) or integrated commutation signals (Hall effect phases).

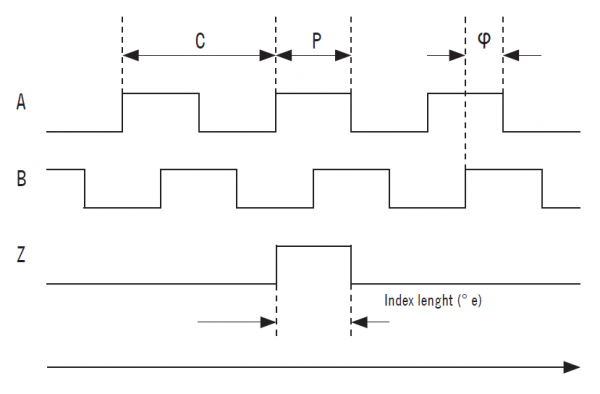

3-channel incremental encoder

The incremental encoder usually provides two types of squared waves, out-of-phase of 90° electrical degrees, which are usually called channel A and B. Channel A gives information only about the rotation speed (number of pulses in a certain unit of time), while channel B provides data regarding the direction of rotation, according to the sequence produced by the two signals. Another signal, called Z or zero channel, is also available; it gives the absolute “zero” position of the encoder shaft and is used as a reference point.

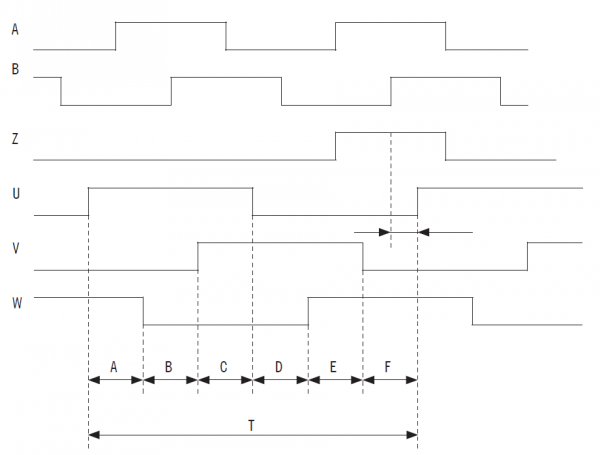

Integrated commutation phases (Hall effect phases)

There are other encoders that integrate additional electrical output signals called incremental encoders with integrated commutation signals, normally used as motor feedback. These additional signals simulate the Hall phases, which are usually employed in brushless motors and are generally formed by magnetic sensors.

In Eltra’s encoders these commutation signals are optically generated and are represented as 3 squared waves, shifted by 120° electrical degrees. These signals are used by the driver that controls the motor to generate the correct voltage phases needed to determine the rotation.

These commutation pulses can be repeated many times within one mechanical revolution, since they depend directly on the number of poles of the connected motor.

For further information, please check the complete PDF on-line.

What is an absolute encoder?

The absolute encoder provides a unique digital code for each angle position of the shaft, storing the value of the current position and, therefore, preventing the loss of information in case of restarting the system or of a power-loss.

The absolute encoder could be of two types:

- Singleturn

- Multiturn

Singleturn absolute encoder

The singleturn absolute encoder allows a precise encoding of the angular position of the shaft, to which the encoder is coupled to, even if the power goes out. Therefore, each single degree position is converted into a specific code (Gray or binary) proportionally to the number of bits.

Multiturn absolute encoder

The multiturn absolute encoder allows a higher number of applications, representing a very interesting extension of the encoders’ action field. Besides the angular tracking of the singleturn system, the multiturn stores also the counting of number of revolutions (360° turns) made.

For further information, please check the complete PDF on-line.

What is an optical encoder?

The most widespread encoders use the optical (or photoelectric) technology to detect signals; this differentiates in two main scanning methods: the transmissive and the reflective one.

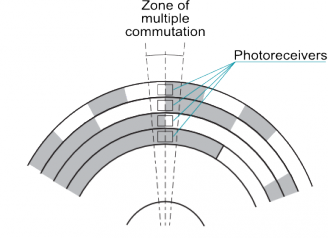

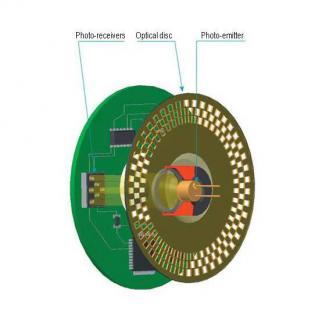

Transmissive optical scanning

In the transmissive optical encoder, the scan system is based on the rotation of a graduated disc - or code wheel - patterned with alternating opaque and clear (transparent) segments; the code wheel is illuminated by an infrared light source positioned perpendicularly to the sensor. The disc beams its image on the surface of several receivers, opportunely masked by another grid (called “collimator”) with the same pitch as the other. The receivers have the task to sense the variations of light that take place during the rotation of the disc, converting them into corresponding electric pulses. In linear transducers the operating principle is similar, with the difference that the motion is detected on a linear reading system.

|

|

| Incremental optical encoder | Absolute optical encoder |

Reflective optical scanning

The reflective optical system is also based on the photoelectric scanning of a code wheel, but in this type of technology the light source and the receiver are in the same surface mount package: the light source illuminates the code wheel formed by darker segments alternated with reflective ones, where the light is reflected and detected by the sensor (receiver), which will transform the variations in corresponding pulses, as per the transmissive system. This type of reading allows reducing the size of the device while maintaining its performances; it’s an ideal solution for those applications that require miniaturized encoders with a high resolution.

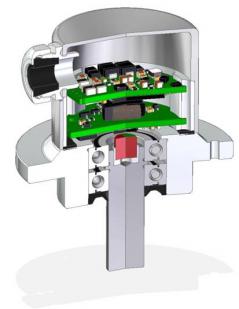

What is a magnetic encoder?

Magnetic encoders employ a signal detection system based on the variation of the magnetic flux generated by a magnet (one or more pole pairs) placed in rotation in front of a sensor, usually fixed to the encoder’s shaft. The variation of the magnetic field is sampled by the sensor and converted into an electric pulse, which determines the position; the magnetic technology could be of two types: on axis or off axis.

The main benefit of the magnetic technology is the absence of contact in the detection system, which helps preventing the wear and it’s therefore quite convenient in terms of costs, since it doesn't require maintenance and has a potentially infinite durability.

Magnetic encoders are particularly suitable for heavy duty applications that require high robustness, speed and a wide range of operating temperature, and they ensure, at the same time, an excellent reliability in the generation of signals.

What is an inductive encoder?

Rotary encoders based on inductive technology with sine/cosine (Sin/Cos) analogue output interface represent an advanced solution in the field of angular position sensing. These devices have been developed to overcome the limitations of fragility and sensitivity to external agents typical of optical encoders.

Operating principle

The operation of an inductive encoder is based on the physical principle of eddy currents.

-

Structure and components: the encoder mainly consists of two elements: the stator (fixed, called sensor board), which contains the excitation electronics for the transmitting coil (implemented as a copper track on a printed circuit board (PCB)) and the receiving coils (also implemented as tracks on a PCB), and the rotor (mobile, called target board), which is a disc (often made of copper or aluminium) with a geometric subdivision depending on the resolution of the product. There are no mechanical contacts or delicate optical discs.

-

Field generation and position detection: the transmitting coil generates an alternating electromagnetic field, which in turn induces secondary voltages in the two receiving coils. The amplitude and phase of these induced voltages vary proportionally to the position of the target above the coils. By demodulating and processing these secondary voltages, the electronics on board the stator acquire a precise signal representing the exact position of the target.

-

Output signal: position information is used by the electronics in the stator to produce output signals that vary sinusoidally/cosinusoidally in relation to the angle.

| |

|

| Stator example (sensor board) | Rotor example (target board) |

Analogue sine/cosine interface

The output of the inductive encoder consists of two phase-quadrature sinusoidal analogue signals: VSen and VCos.

-

Quadrature: The two signals are phase-shifted by exactly 90° electrical degrees. This phase shift is essential because it ensures that, for every angle θ, one signal is at its maximum variation (slope), while the other is at zero or at its maximum value.

VSen∝A⋅sin(P⋅θ)

VCos∝A⋅cos(P⋅θ)

Where A is the amplitude, P is the number of electrical periods per revolution (determined by the rotor pattern), and θ is the mechanical angle.

| Sine/Cosine signals (differential) |

The use of analogue sinusoidal signals is a prerequisite for electronic interpolation. The receiving circuit (often an external ASIC interpolator or one integrated into the drive) samples the Sin and Cos signals and uses the arctangent function to calculate the angle with high precision within a single electrical period:

-

θelectric=arctan(VSen/VCos)

This process allows you to obtain the equivalent of thousands or hundreds of thousands of digital pulses per revolution starting from a low-frequency analogue signal, simulating an encoder with a number of lines much higher than what can be achieved digitally at the same speed. Unlike high-resolution digital encoders, which generate signal frequencies in the MHz range at high speeds (risking signal integrity issues over long distances), the base frequency of Sin/Cos signals remains relatively low (usually in the kHz range), which facilitates signal transmission and processing.

Advantages and applications

Sin/Cos inductive technology is preferred for its robustness and reliability in harsh environments. The main advantages are:

-

Environmental immunity: The operating principle is not affected by common contaminants such as dust, dirt, grease, moisture, oils and condensation. The sensor board can be further protected (e.g. with conforma coating) while the metal disc (rotor) is inherently robust, making these encoders ideal for applications in heavy robotics, machine tools (CNC), offshore installations and the wind power sector.

-

Mounting tolerances: the coupling between the stator and rotor can have wider tolerances in terms of axial and radial misalignment than optical encoders, simplifying installation and reducing precision assembly costs.

-

Feedback for servo motors: these are the standard choice for position and speed feedback in modern servo motors. The quality and smoothness of the Sin/Cos signals enable extremely precise torque and speed control, improving the dynamic performance of the motor.

-

Continuous diagnostics: monitoring the trigonometric relationship VSen2 + VCos2 = constant (known as the Lissajous circle) enables real-time diagnostics of signal integrity, which is essential for safety applications.

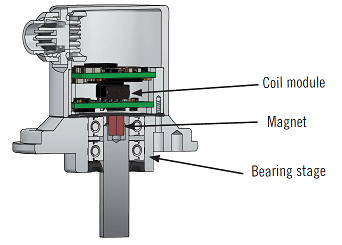

What is the Energy Harvesting Technology?

On the multiturn side, the multiturn counting is enabled utilizing energy harvesting technology. When the shaft is rotating, the magnet mounted on the shaft moves in tandem. The energy-harvesting coil module cuts the moving magnet field, and generates energy as a result. The beauty of the energyharvesting effect is that the same amount of energy is generated independently of the rotation speed. The generated energy is suffi cient to power up the revolution tracking circuitry. Therefore, no miscounts occur even in the absence of external power supply. It can replace traditional gear technology due to absence of wear (no contact technology).

Section of a product with Energy Harvesting Technology

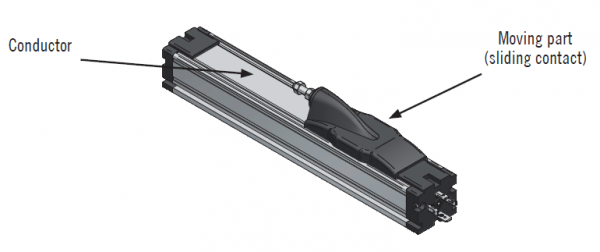

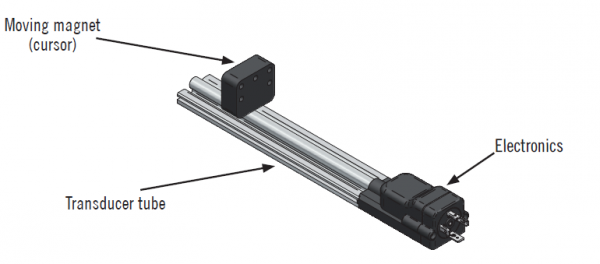

What is a linear transducer?

Linear transducers are used to detect the position and speed of rectilinear mechanical movements.

Also linear transducers vary in accordance to the motion sensing technology and can be of different types.

Incremental linear transducer

The operating principle is similar to the rotary incremental’s one, but in this case the disc is replaced by a stationary opaque strip (called "linear scale") with transparent slits along its surface. These transducers are employed in factory environments on automated operating machines, on counting, display and control systems, for “cut to length” positioning, for certain pitch displacements and, more in general, to display measures of length and thickness.

Potentiometric linear transducer

This type of linear transducer is formed by a wire or a metal layer, winded up in a non-conductor support, and by a movable contact that shifts along the conductor. The operating principle is based on the change in resistance of an electric circuit, caused by the displacement of the object of which the position must be determined. Potentiometers are particularly suitable for the employment in thermoplastic, wood, marble, iron and steel processing machinery and for any application that requires position and motion absolute measurement.

Magnetostrictive linear transducer

Magnetostrictive transducers are based on the magnetostriction principle, for which certain materials expand and contract when they are put into an alternate magnetic field. Key factor of this technology is the absence of electric contact on the slider, which makes the device highly resistant to wear and tear while ensuring great performances in speed and precision.

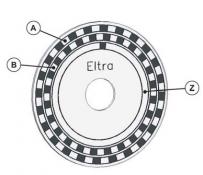

What is the encoder code wheel?

The encoder code wheel (or disc) defines the transmission code of pulses; it is formed by a support made of plastic, glass or metallic material, on which is engraved a pattern of alternated clear (transparent) and opaque segments.

In incremental encoders transparent segments alternate with opaque ones along a single circular ring on the disc; the number of these segments determines the number of pulses and, therefore, also the resolution of the device. Since there is no absolute position in the incremental measure system, it’s often used an additional segment called “zero pulse” as a univocal reference to determine the starting position.

|

| Incremental code wheel |

In absolute encoders transparent segments alternate with opaque ones along several circular rings, according to a pattern that provides the position in a binary code configuration. To avoid encoding errors, a variant of the natural binary code is employed, the Gray code, which has the distinctive characteristic to vary only one binary digit between a code and the following one, ensuring a higher reliability both in code generation and decoding.

|

|

| 2 bit disc with binary code | 2 bit disc with Gray code |

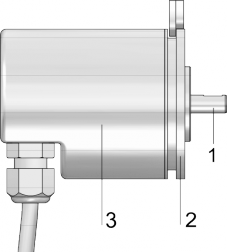

What is the mechanical interface?

The mechanical interface consists in all those components that allow the coupling of the encoder to the machine or device of application, which are:

- An axle, connected to the shaft of the machine in rotation, designed in accordance to the type of fixing:

solid shaft, blind and through hollow shaft;

- A flange, which fixes and adjusts the encoder to its support;

- A case (or body), which contains and protects the disc and the electronic components.

Elastic couplings can also be employed to adapt the fixing between the motor shaft and the encoder.

|

|

|

| Solid shaft | Blind hollow shaft | Through hollow shaft |

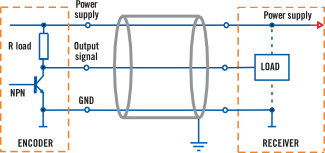

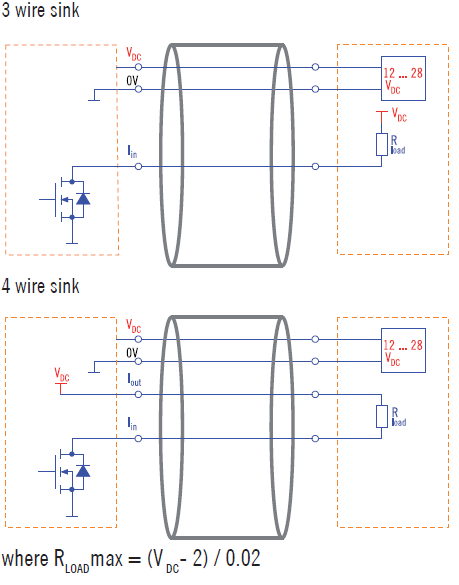

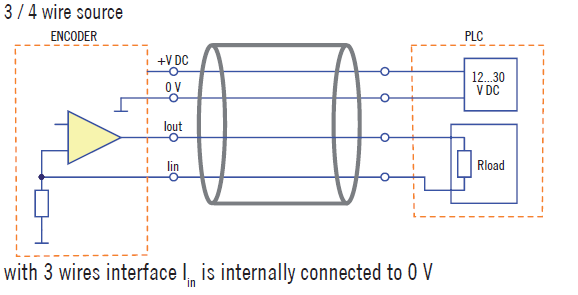

Which are the incremental electronic interfaces?

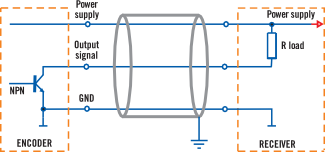

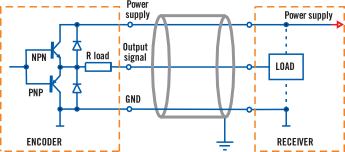

NPN and NPN open collector

This type of electronic output is composed by a NPN transistor and a pull-up resistor used to match the output voltage to the power supply when the transistor is off. It has low saturation levels at 0 Vdc and close to 0 at the positive. It is proportionally influenced by the cable length, pulses frequency and by the load, so these factors should be considered to meet the application’s needs.

The open collector variant differs since it has no pull-up resistor, therefore the collector of the transistor is free from the constraint of the encoder power supply, allowing to obtain signals with different voltage.

|

|

| NPN scheme | NPN open collector scheme |

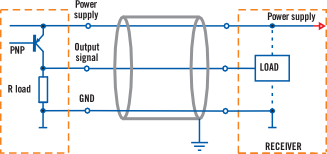

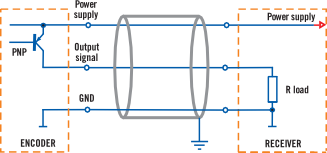

PNP and PNP open collector

Main characteristics and limitations of the PNP interface are the same as for NPN electronics. The main difference lies in the transistor, which is a PNP type. The resistor, if present, is a pull-down one. Therefore, it is connected between the output and 0V.

|

|

| PNP scheme | PNP open collector scheme |

Push-pull

In NPN or PNP electronics the major limitations are caused by the resistor, which works with a much higher impedance than a transistor. To overcome this issue, the Push-Pull circuit uses a complementary transistor, so the impedance is lower for commutation to positive and to zero. This solution increases frequency performances allowing longer cable connections and an optimal data transmission even at high working speed. Saturation signals are low, though higher than in NPN and PNP electronics. It is anyhow possible to apply indifferently the Push-Pull electronics also to NPN or PNP receivers, which is also TTL compatible (5 Vdc power supply).

|

| Push-Pull scheme |

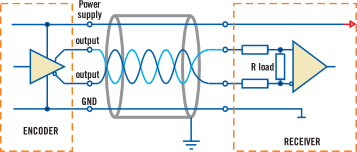

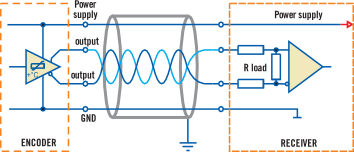

Line-driver

The Line-Driver output is employed when operating environments are particularly exposed to electrical interferences or when the encoder is quite far from the receiver system.

Data transmission and reception work on two complementary channels, so the noise caused by the cross-talk from other cables is reduced. In Line-Driver instead, signals are transmitted and received in «differential» way; in other words, the communication works based on the difference of voltage between complementary channels.

This type of transmission is used in 5 Vdc systems and is compatible also with RS422; it’s also available with power supplies up to 24 Vdc for harsh environments applications.

|

| Line-Driver scheme |

Output stage protection

A highly integrated driver is used to protect outputs from short circuits. This solution is based on an active sensor which controls instantly the temperature reached by the element to be protected. In this way, protection is very effective.

Moreover, it ensures a constant protection against repetitive and permanent short circuits, which is why it is strongly suggested for heavy duty applications.

It’s available for Line-Driver and Push-Pull electronics.

|

| Output stage protection scheme |

For further information, please check the catalogue section Technical Basics.

What is the electronic interface?

The electronic interface consists in all the input and output components that allow both the power supply and the transmission of electric pulses of the encoder.

In the incremental system, the transmission of output signals occurs through one or more channels and could be of different kinds:

NPN and NPN open collector

PNP and PNP open collector

Push-Pull

Line driver

In the absolute system, the transmission of output signals could be analogue (voltage/current) or digital parallel, digital serial (SSI or BiSS), or field-bus type (Eltra employs Profibus DP or Profinet communication protocol for its encoders).

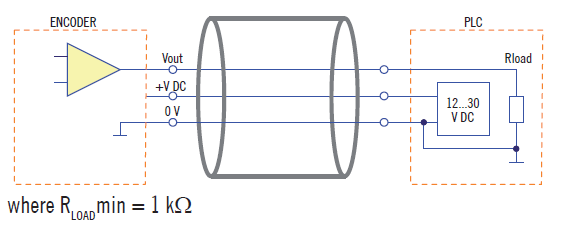

What is the analogue interface?

Analogue interface provides position by current or voltage signals. It can be used as potentiometer replacement.

Voltage range goes from 0 ... 5 V to 0 ... 10 V and current (sink or source configuration) range goes from 0 ... 20 mA to 4 ... 20 mA according to industry standard interfaces.

Voltage output

Current output

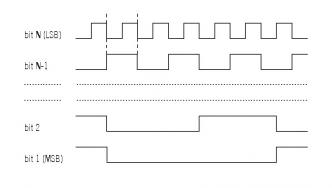

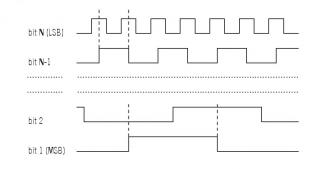

What is the parallel interface?

The parallel output is the standard interface for singleturn and multiturn absolute encoders. These encoders provide the data output regarding the position in a “bit by bit” encoding (according to Gray or binary standards), according to the resolution of the device; parallel transmission requires indeed a wire for each bit, therefore for a higher resolution of the device there will be a higher complexity of the wiring. To reduce the number of wires, other forms of data transmission like the SSI serial interface or field bus protocols (PROFIBUS) have been implemented.

|

|

| Output data in binary format | Output data in Gray format |

For further information, please check the complete PDF on-line.

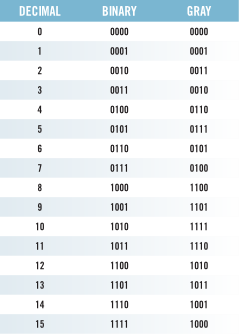

What are Gray and binary codes?

Absolute encoders are so defined since they maintain the absolute position value also after an interruption or a power-loss, so it’s essential that all data referring to the position should be always available. For this purpose binary codes are employed, set by the pattern of transparent and opaque segments placed crosswise or lengthwise on the disc, in relation to the direction of the movement.

Binary code

The natural binary code presents the disadvantage to have more binary digits changing between two consecutive positions. Because of mechanical tolerances, bounces or noise, it could happen that the commutation signals do not operate all at the same time when the state changes, causing intermediate situations that could produce errors in the calculation of the position. To avoid this inconvenient and, therefore, to avoid errors in the output code, an output sync signal (STROBE) is used.

Gray code

In Gray code a single binary digit changes between consecutive steps; the code tracks are read crosswise, with respect to the direction of movement, avoiding encoding errors caused by bits changing in contiguous positions.

What is the SSI interface?

The continuous evolution of the automation field implies a growing request for precision in measurement devices and, therefore, also in absolute encoders. To satisfy this demand, absolute encoders have been designed with always higher resolution, which means an increasing number of bits and, as a consequence, also of wires.

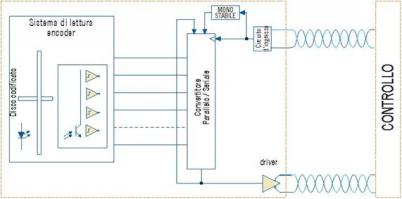

The Synchronous Serial Interface (SSI) was created to solve these setbacks, in order to contain installation costs and simplify the wiring. This interface transmits data in a serial mode by using only two signals (CLOCK and DATA), independently from the number of bits of the encoder.

The position data is obtained by the encoder reading system and continuously transmitted to a parallel/serial converter (based by a “shift register” with parallel loading). When the mono-stable circuit is activated by a clock signal transition, the data is stored and transmitted to the output synchronized with the clock signal.

CLOCK and DATA signals are transmitted differentially (RS422) to enhance immunity from interference and to allow longer transmission distances.

For further information, please check the complete PDF on-line.

| SSI Transducers Eltra |

What is the BiSS interface?

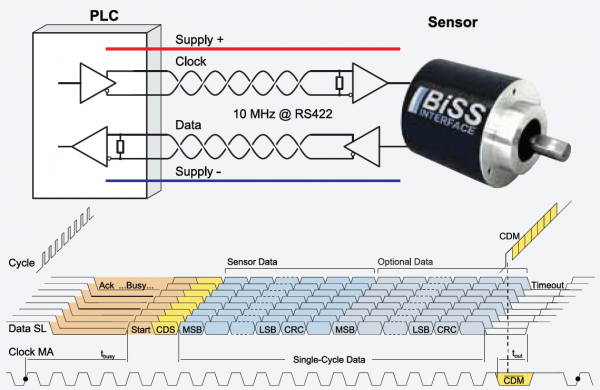

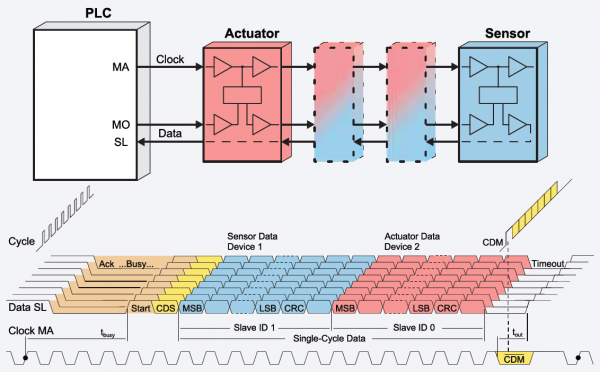

BiSS is an open source digital interface for sensors and actuators. BiSS is hardware compatible to the industrial standard SSI (Serial Synchronous Interface) but offers additional features and options like bidirectional data communication (serial synchronous, continuous data communication) and two unidirectional lines clock and data (cyclic at high speed (up to 10 MHz), line delay compensation for high speed data transfer, request processing times for data generation at slaves, safety capable (CRC, errors, warnings) and bus capability for multiple slaves and devices in a chain.

The advantage of open source protocols is that the selection of components it is not imposed so the end customer can choose the proper products related to the application, increasing the cost-efficency.

Further advantage for the end customer is the compatibility between different manufactures.

Typical BiSS encoder connection

In point-to-point configuration, only one device with one or more slaves (sensors) is connected to the master. The master transmits the clock signal to the slave(s) via the MA line. The SL line carries the sensor data directly from the first slave back to the master. In point-to-point configuration the input SLI of the ’Last Slave’ is connected to ’0’.

In bus configuration, all devices, which may also each include multiple slaves, are connected in a chain. Each slave therefore has two terminals (SLO and SLI) with drivers provided for high speed differential signals if applicable. The MA line supplies the clock signal from the master simultaneously to all slaves and the SLO and SLI lines connect the master and all slaves in a chain.

Multi product BiSS connection and BiSS frame

The BiSS frame (transmission frame) is started by the master with the clock MA, clocked and ended. Here the first rising edge at MA is used for the synchronization of all slaves. It enables the isochronous scanning

of sensor data and the isochronous output of actuator data. With the 2nd rising edge from MA, all slaves set their SLO line to “0” and generate their “Ack” (Acknowledge) signal with it; it remains active (SLO = “0”) until the start bit arrives at the input SLI of the respective slave. The start bit is then passed on synchronously with the clock MA from each slave delayed by one clock pulse, while the CDS bit is either passed on by the slave or is set according to the rules of the control frame. Beginning with the 2nd bit after the start bit and up to the stop bit of the BiSS frame, the data range follows, which transmits the sensor data from the slaves to the master and the actuator data from the master to the slaves. The BiSS frame ends with the BiSS timeout. In this time no further clock pulses are sent to the MA by the master. The inverse state of the MA line during the BiSS timeout is the state of the CDM (Control Data Master) bit. At the end of the data transmission, the master sets its output MO to the idle state “1”. The

slaves then pass on this “1” received at SLI to their output SLO as soon as they have detected the expiration of the timeout themselves. This ensures that the BiSS timeout on the line SL is only signaled to the master when all connected slaves have detected the timeout.

When the BiSS timeout expires, all slaves return to the idle state; all lines are set to the high signal level (“1”) in the process.

Further infomations can be found on the BiSS website.

| BiSS Encoder Eltra |

What is the Modbus protocol?

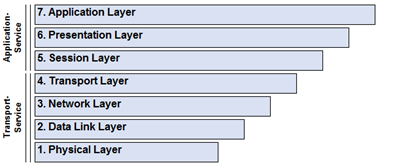

MODBUS is an application layer messaging protocol, positioned at layer 7 of the OSI model. Provides client/server communication between connected devices on different types of buses or networks.

The de facto industry serial standard since 1979, MODBUS continues to enable millions of automation devices to communicate.

MODBUS is a request/response protocol and offers services specified by function codes. MODBUS function codes are elements of Request/Response PDUs.

STRUCTURE OF MODBUS RTU TELEGRAMS

In order to make settings in the device, the respective Modbus registers must be addressed via a telegram. The basic structure of a Modbus telegram is shown below:

| Start | Address | Function | Data | CRC | Stop |

| 3,5 byte | 1 byte | 1 byte | N x 8 bits | 2 bytes | 3,5 bytes |

The data area has a different structure depending on whether the telegram is a request or a reply and on the function code used.

In RTU mode, messages begin with a silent interval of at least 3.5 characters. Depending on the transmission speed set in the network, this interval is most easily implemented as a multiple of the duration of one character.

The first field subsequently transmitted is the device address in the range 01...F7h (247d), (248-255 are reserved for Modbus). Allowed characters for all fields: hexadecimal 0-9, A-F. Networked devices constantly monitor the network bus, even during ‘silence’ intervals.When the first field (address field) is received, the device decodes it to determine whether the message is directed to it. After the last character transmitted, an identical interval of at least 3.5 characters indicates the end of the message, a new message can begin after this interval.

The complete telegram must be transmitted as a continuous data stream. In the case of a silent interval of more than 1.5 characters before the end of the telegram, the receiving device deletes the message and assumes that the next byte is the address field of a new message.

Similarly, if a new message begins before the end of the 3.5 character silence interval, the receiving device will consider this new message as a continuation of the previous message. This will trigger an error, as the value in the final CRC field will not be valid for combined messages.

| Encoder Eltra Modbus |

What is the CANopen protocol?

CAN physical and transport layer

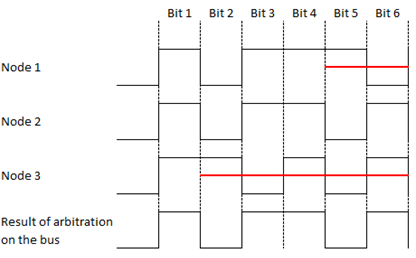

CAN is a field bus. It operates with the CSMA/CA (Carrier Sense Multiple Access / Collision Avoidance) method. It means that collisions during bus access

are avoided by a so called bitwise arbitration. The bits are coded NRZ-L (Non Return to Zero - Low).

A cyclic redundancy check (CRC) and other safety mechanisms provide a secure transmission. For synchronisation a mechanism called "bit stuffing" is used. CAN is a multi-master system, i.e. several equal bus nodes can be connected without a bus master supervising the communication. In principle a CAN bus can be realized with copper wire or in fibre optic cable.

The common CAN implementation with copper wire operates with differential signals, transmitted via two wires: CANHIGH, CANLOW. Therefore CAN has a good common mode rejection ratio.

Data is transmitted with bits that can either be dominant or recessive. The dominant (0) always overwrites the recessive (1).

The topology of a CAN network is a line, which can be extended by stubs. The maximum length of a stub is limited to 0,5m.

The network always has to be terminated on both ends with 120 Ohm each (between CANHIGH and CANLOW). Other locations or values are not allowed.

The arbitration mentioned before is used to control the bus access of the nodes by prioritization of the CAN-Identifier of the different messages.

Every node monitors the bus. If more than on node wants access on the bus, the node with the highest priority of the messages ID succeeds and the other

nodes retreat until there is "silence" on the bus (see below example). Technically the first dominate bit of the ID send overwrites the corresponding recessive

bit of the other IDs. In case that more than one node uses the same CAN-ID an error occurs only at a collision within the rest of the frame.

In principle a CAN-ID should only be used by a single node.

Example of arbitration..

Due to the arbitration there is a ranking of the messages. The message with the lowest ID has the highest priority and therefore it has almost instant access on the bus. The exception is that an ongoing transmission will not be interrupted. So time critical messages should be assigned to the high priority CAN-IDs, but even then there is no determination in the time of transmission (non-deterministic transmission).

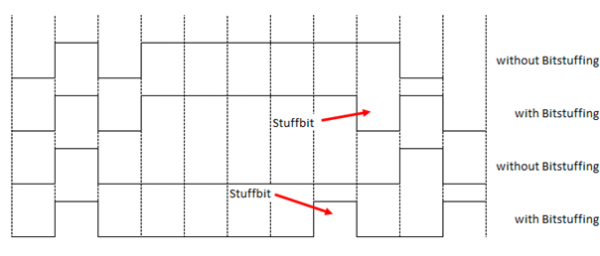

For the arbitration all nodes have to be synchronised. Due to the lack of a separate clock signal, the transmission of many identical bits in line would lead to the loss of synchronisation. The so called bit-stuffing is used to prevent this case. After five equal bits a complementary bit will be inserted into the transmission (the application will not notice). So the nodes can keep up resynchronising on the bit edges (see below figure).

Bitstuffing

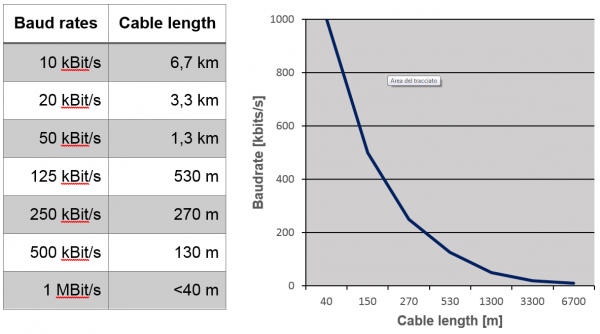

A CAN network can operate with baud rates up to 1 Mbit/s.

Due to the necessary synchronisation of the nodes, the maximum delay caused by the length of the cable has to be limited.

The limitation corresponds with the baudrate. There is a common recommendation of the maximum cable length at several baud rates:

CAN baud rates and recommended cable length limits

CANopen

CANopen is a specified higher protocol (layer 7 protocol)

ISO-OSI Model

With CANopen it is possible to transfer larger amounts of data, emergency telegrams and process data.

CANopen describes how the communication is performed. That means that parameters to configure a device are transmitted in a defined form (profile).

A CANopen profile defines objects representing the different functions of a device. These objects form a table called object dictionary.

The communication profile defines the basic services and parameters of a CANopen device (e.g. service data objects SDOs, process data objects PDOs, used CAN-IDs, etc.).

The device profile defines the specific functions of a device family (e.g. encoders, i/o devices, ...).

For encoders the device profile is the encoder profile CiA 406.

| CANopen Encoder Eltra |

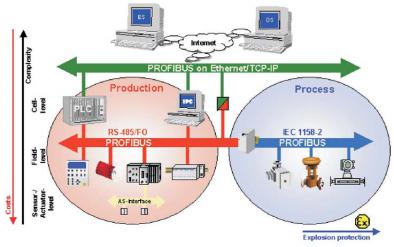

What is the Profibus protocol?

Profibus (Process Field Bus) is a serial communication standard for devices connected to automation networks (field bus). It is an open protocol defined by the DIN 19245 that became European standard as EN 50170 volume 2.

Profibus is promoted by Siemens and widespread all over Europe. Thanks to the definition of three different communication profiles DP, FMS and PA, this field bus meets many of the requirements in the automation system, starting from applications that need to change cyclically a small number of bits at a very high speed (Profibus DP), or managing quite complex communications between “intelligent” devices (Profibus FMS), up to tasks strictly related to the automation process (Profibus PA).

Eltra’s encoders employ the DP version (Decentralized Periphery), which is the standard solution to manage devices by a bus, that is: I/O modules, sensors/transducers or actuators on a low level in automation systems.

For further information, please check the complete PDF on-line.

| Profibus Encoder Eltra |

What is the Profinet protocol?

The ever-shorter innovation cycles for new products makes the continuous evolution of automation technology necessary. The use of fieldbus technology has been a significant development in the past few years. It has made possible to migrate from centralized automation systems to decentralized ones. PROFIBUS, as the global market leader, has set the benchmark here for 25 years. In today’s automation technology, Ethernet and information technology (IT) are increasingly calling the shots with established standards like TCP/IP and XML.

Integrating information technology into automation opens up significantly better communication options among automation systems, extensive configuration and diagnostic possibilities, and network-wide service functionality.

These functions have been integral components of PROFINET from the outset. PROFINET is the innovative open standard for Industrial Ethernet.

PROFINET satisfies all requirements of automation technology; whether the application involves production automation, process automation, or drives (with or without functional safety), PROFINET is the first choice across the board. As a technology that is standard in the automotive industry, widely disseminated in machine building, and well-proven in the food and packaging and logistics industries, PROFINET has found its way into all application areas.

New application areas are constantly emerging, such as marine and rail applications or even day-to-day operations, for example, in a beverage shop. And now: the new PROFIenergy technology profile will improve the energy balance in production processes. PROFINET is standardized in IEC 61158 and IEC 61784.

The ongoing further development of PROFINET offers users a long-term view for the implementation of their automation tasks.

For plant and machine manufacturers, the use of PROFINET minimizes the costs for installation, engineering, and commissioning.

For plant owners, PROFINET offers ease of plant expansion and high plant availability due to autonomously running plant units and low maintenance requirements. The mandatory certification for PROFINET devices also ensures a high quality standard.

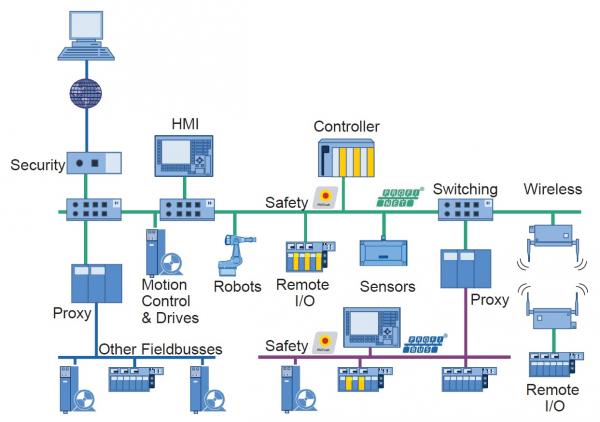

Example of plant network

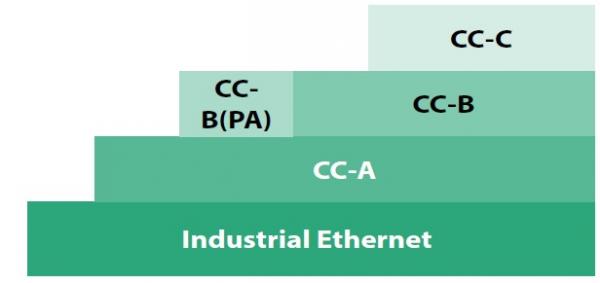

The scope of functions supported by PROFINET IO is clearly divided into conformance classes ("CC"). These provide a practical summary of the various minimum properties.

There are three conformance classes that build upon one another and are oriented to typical applications.

Profinet conformance classes

CC-A provides basic functions for PROFINET IO with RT communication. All IT services can be used without restriction. Typical applications are found, for example, in business automation. Wireless communication is specified for this class.

CC-B extends the concept to include network diagnostics via IT mechanisms as well as topology information. The system redundancy function important for process automation is contained in an extended version of CC-B named CC-B(PA).

CC-C describes the basic functions for devices with hardware-supported bandwidth reservation and synchronization (IRT communication) and is thus the basis for isochronous applications.

The conformance classes also serve as the basis for the certification and the cabling guidelines.

A detailed description of the CCs can be found in the document “The PROFINET IO Conformance Classes” [7.042].

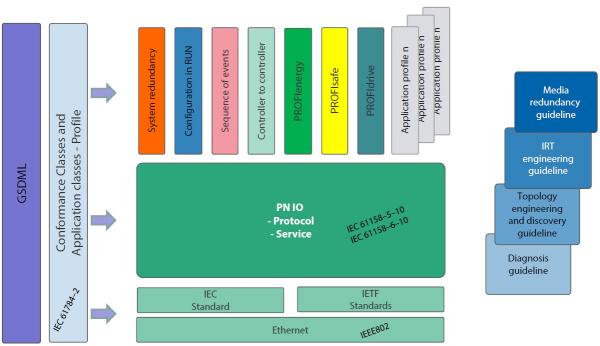

The PROFINET concept was defined in close collaboration with end users based on standard Ethernet according to IEEE 802 in IEC 61158 and IEC 61784. Figure below lists additional specifications of the functionalities in the form of different joint profiles. These form the basis for device or application-specific profiles. Instructions are created for the necessary planning, engineering, and commissioning steps.

The basics for this form the guidelines for engineering PROFINET systems.

PROFINET IO follows the Provider/Consumer model for data exchange.

Configuring a PROFINET IO system has the same look and feel as in PROFIBUS.

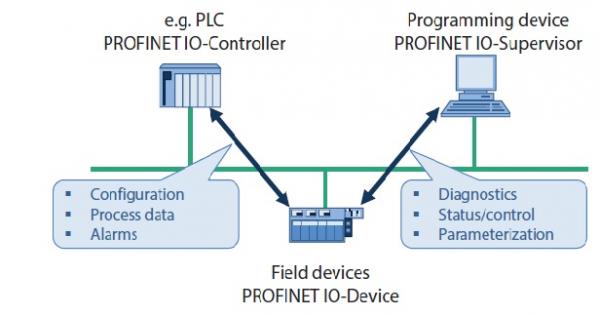

The following device classes are defined for PROFINET IO:

IO Controller: this is typically the programmable logic controller (PLC) on which the automation program runs. This is comparable to a class 1 master in

PROFIBUS. The IO controller provides output data to the configured IO devices in its role as provider and is the consumer of input data of IO devices.

IO Device: an IO device is a distributed I/O field device that is connected to one or more IO controllers via PROFINET IO. It is comparable to the function of a slave in PROFIBUS. The IO device is the provider of input data and the consumer of output data.

IO Supervisor: this can be a Programming Device (PD), personal computer (PC), or human machine interface (HMI) device for commissioning or diagnostic purposes and corresponds to a class 2 master in PROFIBUS.

A plant unit contains at least one IO controller and one or more IO devices. IO supervisors are usually integrated only temporarily for commissioning or troubleshooting purposes.

Further infomations can be found on the Profinet website.

| Profinet Encoder Eltra |

What is the EtherCAT protocol?

EtherCAT is Industrial Ethernet and utilizes standard frames and the physical layer as defined in the Ethernet Standard IEEE 802.3. However, it also addresses the specific demands faced in the automation industry, where:

· there are hard real-time requirements with deterministic response times

· the system is usually made up of many nodes, each only having a small amount of cyclic process data

· hardware costs are even more important than in IT and office applications

The above requirements make using a standard Ethernet network at the field level practicallyimpossible. If an individual Ethernet telegram is used for each node, the effectivedata rate sinks significantly for just a few bytes of cyclic process data: the shortest Ethernet telegram is 84 bytes long (including the Inter Frame Gap), of which 46 bytes can be used for process data. For example, if a drive sends 4 bytes of process data for the actual position and status information and receives 4 bytes of data for the target

position and control information, the effective data rate for both telegrams sinks to 4/84 = 4.8 %. Additionally, the drive usually has a reaction time that triggers the transmission of the actual values after receiving the target values. At the end, not much of the 100MBit/s transfer rate remains.

Protocol stacks, such as those used in the IT world for routing (IP) connection (TCP), require additional overhead for each node and create further delays through the stack runtimes.

EtherCAT overcomes the difficulties described in the previous section with its high performing mode of operation, in which a single frame is usually sufficient to send and receive control data to and from all nodes!

The EtherCAT master sends a telegram that passes through each node. Each EtherCAT slave device reads the data addressed to it on the fly, and inserts its data in the frame as the frame is moving downstream. The frame is delayed only by hardware propagation delay times. The last node in a segment or branch detects an open port and sends the message back to the master using Ethernet technology’s full duplex feature.

The telegram’s maximum effective data rate increases to over 90 %, and due to the utilization of the full duplex feature, the theoretical effective data rate is even greater than 100 MBits/s.

The EtherCAT master is the only node within a segment allowed to actively send an EtherCAT frame; all other nodes merely forward frames downstream. This concept prevents unpredictable delays and guarantees real-time capabilities.

The master uses a standard Ethernet Media Access Controller (MAC) without an additional communication processor. This allows a master to be implemented on any hardware platform with an available Ethernet port, regardless of which real-time operating system or application software is used.

EtherCAT slave devices use an EtherCAT Slave Controller (ESC) to process frames on the fly and entirely in hardware, making network performance predictable and independent of the individual slave device implementation.

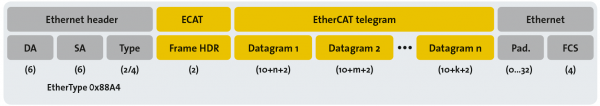

EtherCAT in a standard Ethernet frame (according to IEEE 802.3)

EtherCAT embeds its payload in a standard Ethernet frame. The EtherCAT frame is identified with the Identifier (Ox88A4) in the EtherType field. Since the EtherCAT protocol is optimized for short cyclic process data, the use of bulky protocol stacks, such as TCP/IP or UDP/IP, can be eliminated.

To ensure Ethernet IT communication between the nodes, TCP/IP connections can optionally be tunneled through a mailbox channel without impacting real-time data transfer.

During startup, the master device configures and maps the process data on the slave devices. Different amounts of data can be exchanged with each slave, from one bit to a few bytes, or even up to kilobytes of data.

The EtherCAT frame contains the frame header and one or more datagrams.

The datagram header indicates what type of access the master device would like to execute:

· there are hard real-time requirements with deterministic response times

· the system is usually made up of many nodes, each only having a small amount of cyclic process data

· hardware costs are even more important than in IT and office applications

Logical addressing is used for the cyclical exchange of process data. Each datagram addresses a specific part of the process image in the EtherCAT segment, for which 4 GBytes of address space is available. During network startup, each slave device is assigned one or more addresses in this global address space. If multiple slave devices are assigned addresses in the same area, they can all be addressed with a single datagram. Since the datagrams completely contain all the data access related information, the master device can decide when and which data to access. For example, the master device can use short cycle times to refresh data on the drives, while using a longer cycle time to sample the I/O; a fixed process data structure is not necessary. This also relieves the master device in comparison to in conventional fieldbus systems, in which the data from each node had to be read individually, sorted with the help of the process controller, and copied into memory.

With EtherCAT, the master device only needs to fill a single EtherCAT frame with new out put data, and send the frame via automatic Direct Memory Access (DMA) to the MAC controller.

When a frame with new input data is received via the MAC controller, the master device can copy the frame again via DMA into the computer’s memory – all without the CPU having to actively copy any data.

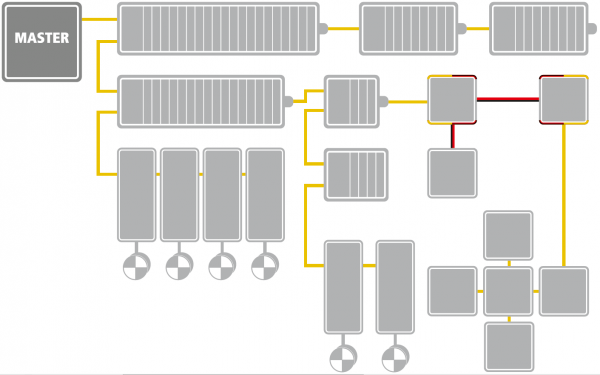

Flexible topology: line, tree, star, or daisy-chain

Line, tree, star, or daisy-chain: EtherCAT supports almost all of topologies. EtherCAT makes a pure bus or line topology with hundreds of nodes possible without the limitations that normally arise from cascading switches or hubs.When wiring the system, the combination of lines with branches or drop lines is particularly beneficial: the ports necessary to create branches are directly integrated in many I/O modules, so no additional switches or active infrastructure components are required.

When wiring the system, the combination of lines with branches or drop lines is particularly beneficial: the ports necessary to create branches are directly integrated in many I/O modules, so no additional switches or active infrastructure components are required.

The star topology, the Ethernet classic, can also naturally be utilized.

Modular machines or tool changers require network segments or individual nodes to be connected and disconnected during operation. EtherCAT Slave Controllers already include the basis for this Hot Connect feature. If a neighboring station is removed, then the port is automatically closed so the rest of the network can continue to operate without interference. Very short detection times faster than 15 microseconds guarantee a smooth changeover.

EtherCAT offers a lot of flexibility regarding cable types, so each segment can use the exact type of cable that best meets its needs. Inexpensive industrial Ethernet cable can be used between two nodes up to 100m apart in 100BASE-TX mode. Furthermore, the protocol addition EtherCAT P enables the transmission of data and power via one cable.

This option enables the connection of devices such as sensors with a single line. Optical fibres (such as 100BASE-FX) can also be used, for example for a node distance greater than 100 m. The complete range of Ethernet wiring is also available for EtherCAT.

Up to 65,535 devices can be connected to one EtherCAT segment, so network expansion is virtually unlimited. Because of the practically unlimited number of nodes, modular devices such as sliced I/O stations can be designed in such a way that each module is an

EtherCAT node of its own. Hence, the local extension bus is eliminated; the high performance of EtherCAT reaches each module directly and without any delays, since there is no gateway in the bus coupler or head station any more.

In order to configure and diagnose slave devices, it is possible to access the variables provided for the network with the help of acyclic communication. This is based on a reliable mailbox protocol with an auto-recover function for erroneous messages.

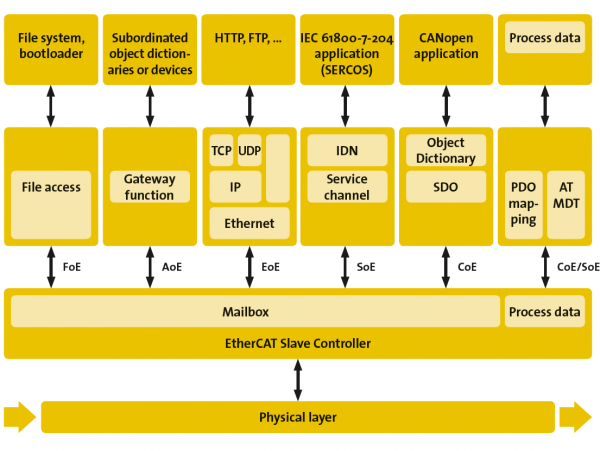

In order to support a wide variety of devices and application layers, the following EtherCAT communication profiles have been established:

· CAN application protocol over EtherCAT (CoE)

· Servo drive profile, according to IEC 61800-7-204 (SoE)

· Ethernet over EtherCAT (EoE)

· File access over EtherCAT (FoE)

· ADS over EtherCAT (AoE)

A slave device isn’t required to support all communication profiles; instead, it may decide which profile is most suitable for its needs. The master device is notified which communication profiles have been implemented via the slave device description file.

With the CoE protocol, EtherCAT provides the same communication mechanisms as in CANopen®-Standard EN 50325-4: Object Dictionary, Mapping of Process Data Objects (PDO) and Service Data Objects (SDO). Even the network management is similar.

This makes it possible to implement EtherCAT with minimal effort in devices that were previously outfitted with CANopen, and large portions of the CANopen Firmware are even reusable. Optionally, the legacy 8-byte PDO limitation can be waived, and it’s also possible to use the enhanced bandwidth of EtherCAT to support the upload of the entire Object Dictionary. The device profiles, such as the drive profile CiA 402, can also be reused for EtherCAT.

Different communication profi les can coexist in the same system

EtherCAT®, EtherCAT P®, and Safety over EtherCAT® are registered trademarks and patented technologies, licensed by Beckhoff Automation GmbH, Germany.

CANopen® is a registered trademark of the CAN in Automation e.V. Other text and pictures copyright Ethercat Technology Group.

| EtherCAT Encoder Eltra |

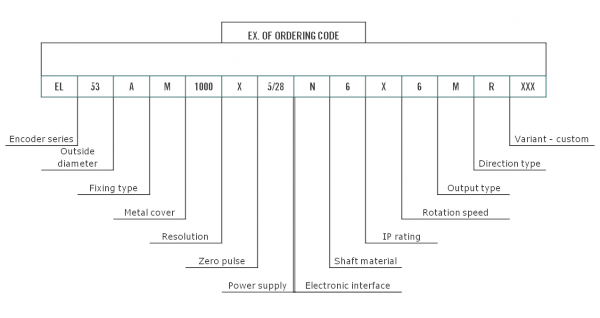

How to read Eltra’s ordering code

Please find below an example of an ordering code of Eltra’s product, with which it’s possible to identify or verify the main characteristics of the device.

All the variants and the mechanical and electrical specifications available for each encoder series are indicated in the Datasheet, which can be downloaded in correspondence to each product page.

En

En It

It