Technical Support

Our skilled Engineers and Technical Staff are at Client's disposal to solve doubts and technical queries, besides giving suggestions regarding the best choice of Eltra's product, in accordance to the specific application needs.

To request support pre- and post-sale, please fill the Technical Support Form on-line, providing all the details necessary to indentify and to help solving the problem for which the assistance is requered.

For urgent matters, please contact our Offices, from Monday to Friday, from 08:30 a.m. to 12:30 p.m. and from 1:30 p.m. to 5:30 p.m. (GMT +1).

Sales Assistance

For enquiries regarding sales, please send us an email to eltra.it@broadcom.com to receive rapidly support and information about the status of shipments and deliveries, product availability and contact details of our area distributor or reseller.

Our Sales Team will do their best to reply as soon as possible.

For urgent matters, please contact our Offices, from Monday to Friday, from 08:30 a.m. to 12:30 p.m. and from 1:30 p.m. to 5:30 p.m. (GMT +1).

Express Service

Machinery breakdown?

Forgot to place the order? No problem!

Emergency?

Eltra offers an easy and efficient solution to solve your encoder’s urgency.

Thanks to our well-established ‘Express 24’ and ‘Express 48’ Services, you may request the shipment of Eltra’s encoders that you need,

within 24 or 48 hours at your choice, so that you can restart the activity of the plant in the shortest time possible.

For further information, please check the terms and conditions of the service and - if you don't already have it - a request to receive the form by e-mail at express.eltra@broadcom.com.

Return Material Authorization Request (RMA)

Please review carefully the Return Terms available in the on-line PDF.

To get the RMA #, please:

1. Ask for the latest TMS004 for at support.eltra@broadcom.com

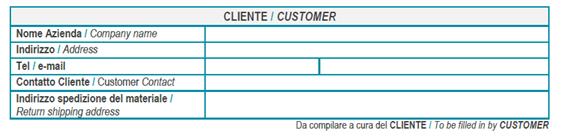

2. Fill the Customer section:

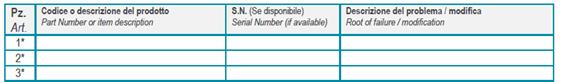

3. Fill the product data and describe the reported problem:

4. Accept the Return Terms:

![]()

5. Send the duly filled form only in .doc or .docx format to: support.eltra@broadcom.com

Our Support team will notify you the acceptance of the Return request, if applicable.

If accepted by Eltra, our Support team will provide the RMA # and the RETURN REASON to be reported within ths shipping documents.

The form approved by Eltra has be to included to the Delivery Note of the goods for which the return had been accepted.

Frequently Asked Questions (FAQ)

Eltra's products are developed and manufactured following all the required procedure to ensure the top quality of products, and singularly tested in our Headquarters before being delivered to the Client.

Most of the malfunctioning of the device are due to an incorrect installation. We strongly recommend to read carefully data-sheet and all the technical documentation before proceeding with the installation of the encoder and to ensure that it's done only by qualified staff.

Please find below some of the most frequent queries that we receive and the procedure to follow in order to identify and/or solve the problem.

| There is no output |

|

| The product is not counting correctly |

|

| The product presents signal noise |

|

| Only one channel is working (incremental encoders) |

|

| The encoder is counting in only one direction (incremental encoders) |

|

| Input index is not working properly |

|

| Other possible problems |

|

Our Technical Support Team is at disposal for assisting and helping to solve doubts and inquiries regarding the correct installation of Eltra's products.

Please fill in the Technical Support Form to require clarification and support.

Correspondence between EL and ER series

Our Research & Development Team is continuously searching for new solutions and improvements to the electronics and mechanical performance of our transducers.

As a result of several technical modifications and implementations, the optical incremental "EL" encoder series has been updated by the new "ER" series.

The "ER" encoder series are interchangeable with the previous "EL", having the same design though with interesting application benefits:

• Increase of temperature range

• Increase of operating frequency

Please find below a comparative scheme between "EL" and "ER" series:

| EL 30 | ER 30 | ||

| Operating temperature [°C] | -10 / +60 | -25 / +85 | |

| Max frequency [kHz] | 100 | 220 | |

| Go to product page for full details | |||

| EL 38 | ER 38 | ||

| Operating temperature [°C] | -10 / +60 | -20 / +85 | |

| Max frequency [kHz] | 150 | 220 | |

| Go to product page for full details | |||

| EH 40 | EL 40 | ER 40 | |

| Operating temperature [°C] | 0 / +60 | -10 / +60 | -25 / +85 |

| Max frequency [kHz] | 40 | 150 | 220 |

| Go to product page for full details | |||

| EL 53 | ER 53 | ||

| Operating temperature [°C] | -10 / +60 | -25 / +85 | |

| Max frequency [kHz] | 300 | 500 | |

| Go to product page for full details |

|||

| EL 58 | ER 58 | ||

| Operating temperature [°C] | -10 / +60 | -25 / +85 | |

| Max frequency [kHz] | 300 | 500 | |

| Go to product page for full details | |||

| EL 63 | ER 63 | ||

| Operating temperature [°C] | -10 / +60 | -25 / +85 | |

| Max frequency [kHz] | 300 | 500 | |

| Go to product page for full details | |||

| EL 72 | ER 72 | ||

| Operating temperature [°C] | -10 / +60 | -25 / +85 | |

| Max frequency [kHz] | 300 | 500 | |

| Go to product page for full details |

|||

| EL 90 | ER 90 | ||

| Operating temperature [°C] | -10 / +60 | -25 / +85 | |

| Max frequency [kHz] | 300 | 500 | |

| Go to product page for full details | |||

| EL 115 | ER 115 | ||

| Operating temperature [°C] | -10 / +60 | -25 / +85 | |

| Max frequency [kHz] | 300 | 500 | |

| Go to product page for full details | |||

Meaning of .V2, .L, .T suffixes

Our Research & Development Team is continuously searching for new solutions and improvements to the electronics and mechanical performance of our transducers.

As a result of several technical modifications and implementations, the following suffix had been identified:

- .V2 (only for EMB series): the EMB updated series - whose description ends with .2V - is fully intercheangeable - both mechanical and electronically - with the previous one.

| EMB | .1V | .2V |

| Max Frequency [KHz] | 100 | 200 |

| Working Temperatureo [°C] | 0/+50 | -20/+85 |

- .L: only for internal use, it doesn't represent any change from Customer perspective

- .T: it represents an extended temperature range compared to the standard version (10/+70 °C, -10/+100°C only for some EL/EF49 resolutions.)

End Of Life | Product Change Notification

As part of our on-going product lifecycle management process, we have identified products that will be transitioned to an "End-of-Life" status or a Product Change Notification. Products targeted for end-of-life may be available for a last time buy option (LTB) prior to being made obsolete, however quantities are limited and special requirements may apply.

Q. What are the last time buy conditions and dates?

A. All purchase orders are non-cancelable and non-returnable. If a LTB is offered, the following dates apply:

- Date of last order acceptance: last date of order acceptance of the order, or until stock runs out.

- Date for last shipments: latest delivery date

Q. Is there a replacement product?

A. If there is any product indicated as replacement, please check carefully the specs and take note that the recommended parts may or may not be drop-in replacement; they may be the closest replacement available.

Please don't hesitate to contact us (Tel: +39 0444 436489 | support.eltra@broadcom.com) if you have any questions or concerns about EOL and PCNs.

En

En It

It